| Material |

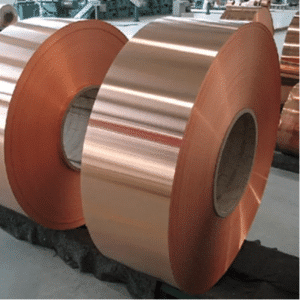

Red Copper |

| Cu (Min) |

≥99.8% |

| Alloy Or Not |

Non-Alloy |

| Place of Origin |

Guangdong, China |

| Application |

Lithium ion battery |

| Width |

Customized |

| Grade |

copper |

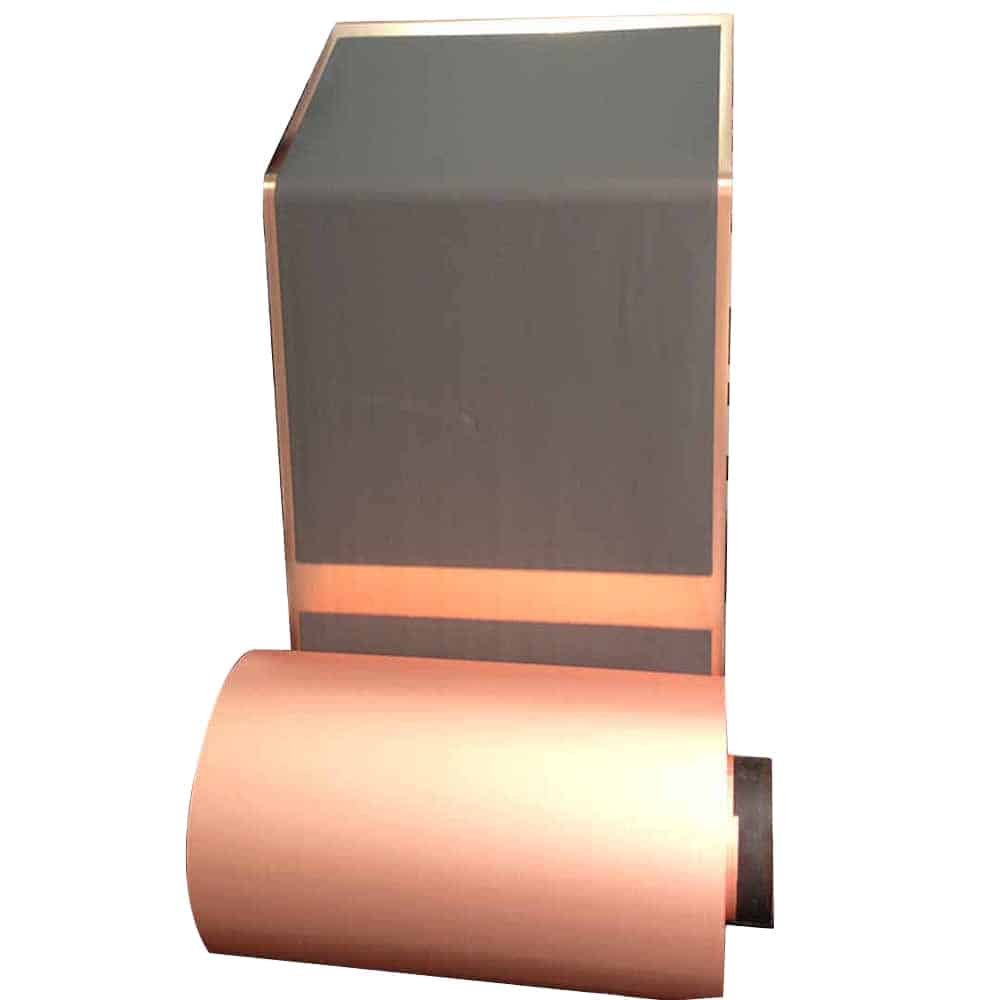

| Model Number |

NS-BCF005 |

| Brand Name |

NSfoil |

| Processing Service |

Cutting |

| Product Name |

copper foil |

| Thickness |

6/9/12/14/16/20um |

| Area Ratio |

85~200g/m2 |

| strength of extension |

≥294 N/mm2 |

| ductility |

≥3% |

| surface roughness |

≤0.3μm |

| wettability |

≥32 mN/m |

| Usage |

lithium battery current collector |

| Length |

Customize |

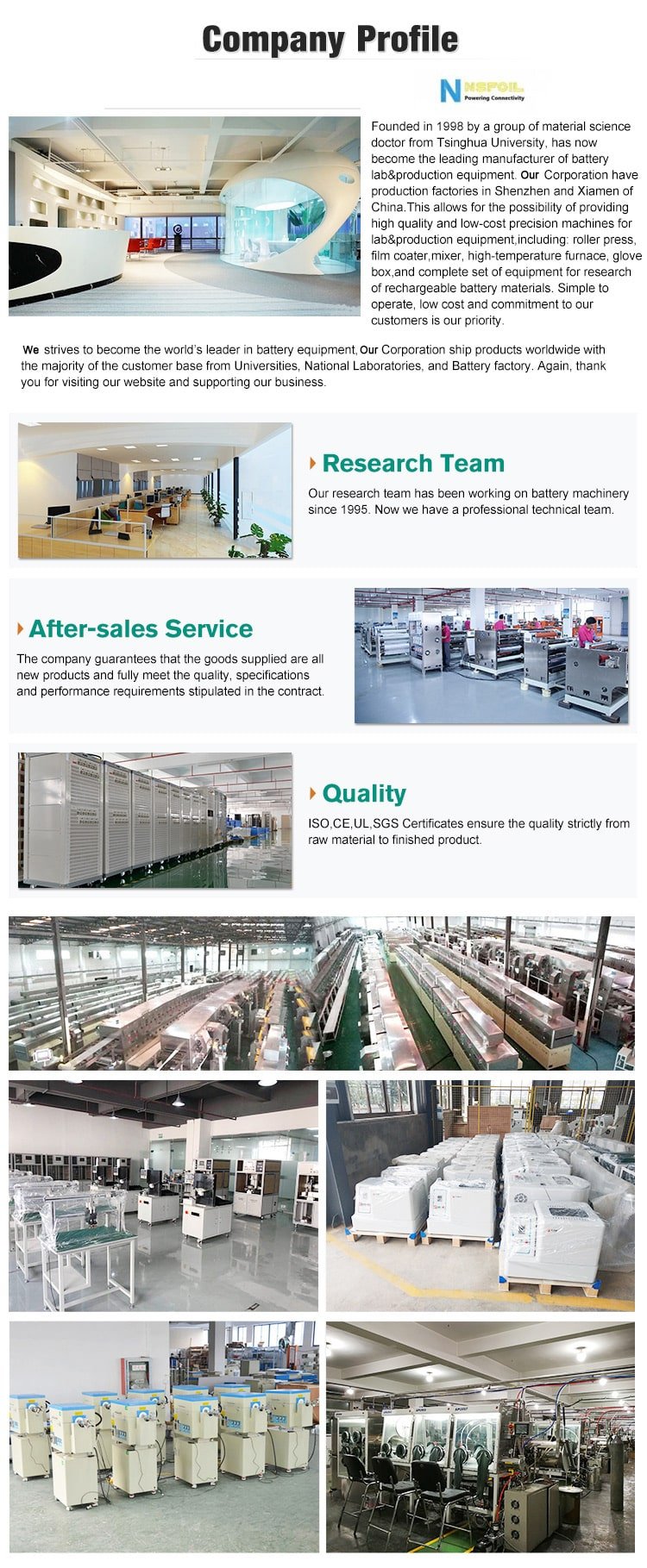

Advantage:

◎ Reduces the weight of current collector.

◎ lmprove the active substance and the adhesion of current collector.

◎ Reduce interface resistance and reduce battery resistance.

◎ Reduce polarization, increase battery rate charging and discharging performance and active material gram capacity play.

◎ Reduce heat of battery, improve battery safety.

◎ Increase the migration rate of lithium ions.

◎ Improve battery energy density.

Product Features

1. Thickness: Copper foil’s ultrathin thickness of 6um makes it highly efficient in battery production while simultaneously improving weight and bulk reduction performance.

2. High Purity Copper Foil: Copper foil made with high purity copper is essential in producing batteries, since any impurities could negatively affect performance and compromise battery quality. Optimum performance requires using copper with high purity content so as to guarantee optimal levels of performance for battery production.

3. Outstanding Conductivity: Copper foil has proven itself an exceptional conductor of electricity, making it a key element of batteries with its superior conductivity levels contributing significantly to improving overall battery efficiency.

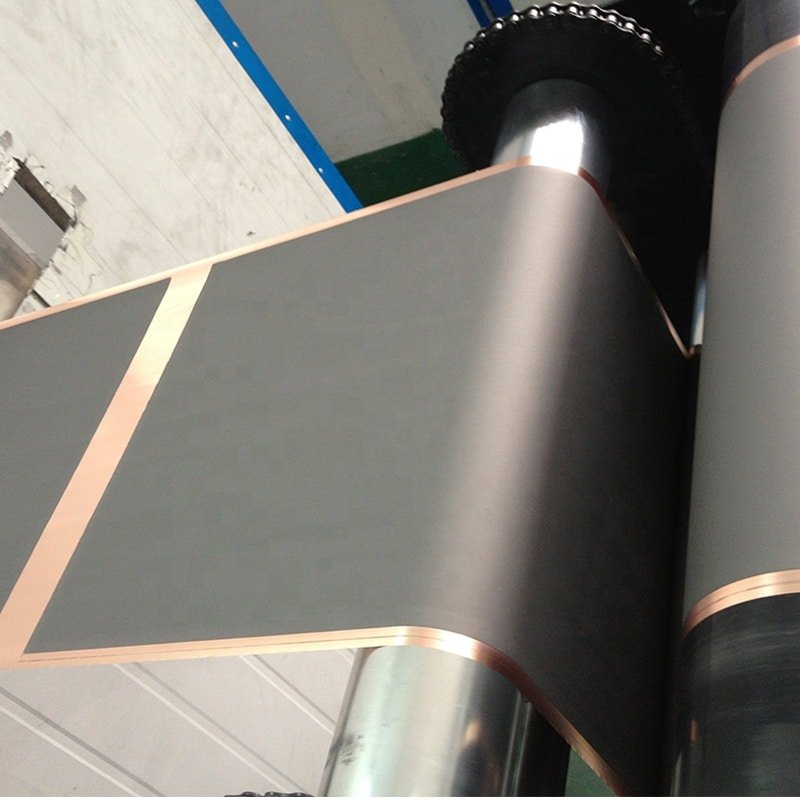

4. Micropore Structure: Copper foil’s microporous structure offers excellent adhesion for active materials (Li-ion batteries), increasing energy density while decreasing internal resistance.

5. Roll Size: With its 2kg roll size and bulk packaging design, this copper foil is well suited for high-volume battery production processes. Handling and storage become much simpler.