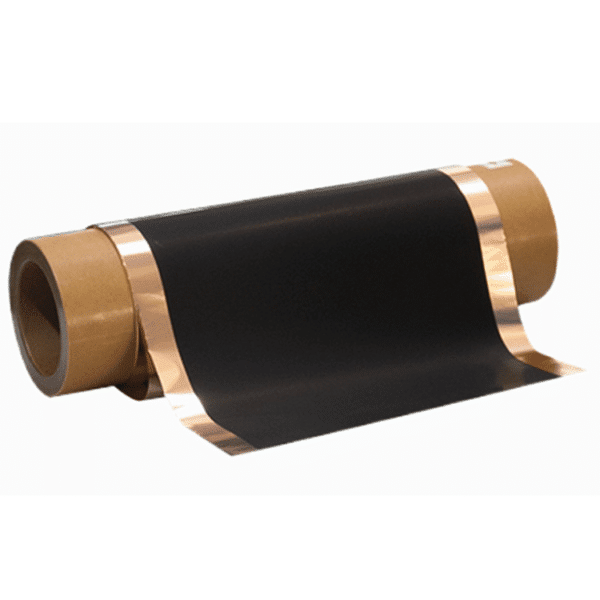

Features

1. High Conductivity: Carbon-coated copper foil boasts high electrical conductivity, making it an excellent material to efficiently collect current in lithium battery systems.

2. Low Internal Resistance: Carbon coating on copper foil helps lower internal resistance of batteries, leading to improved energy efficiency and longer battery lifespan.

3. Chemical Stability: The carbon coating provides chemical resistance, protecting copper foil against electrolytes that could corrode it and prolonging battery lifespan and durability.

4. Increased adhesion: The carbon coating encourages increased adhesion between copper foil and active materials, providing strong bonding while decreasing risk of delamination or detachment during battery operation.

5. Uniformity: Uniform carbon coating helps ensure uniform current density distribution across electrode surfaces, thus minimizing hotspots and increasing safety and stability of batteries.

6. Surface Smoothness: Carbon-coated copper foil typically features a smoother surface than its uncoated counterpart, providing better contact between active materials and increasing battery efficiency overall.

7. Lightweight and Flexible: Carbon-coated copper foil is lightweight and flexible, making it suitable for numerous manufacturing processes and battery designs, including those requiring bending or shaping.

8. Heat Dissipation: Copper has excellent thermal conductivity, while carbon coating further aids heat dissipation – helping ensure optimal operating temperatures within battery cells.

9. Compatibility: Carbon-coated copper foil is compatible with all types of lithium batteries, including lithium-ion, lithium polymer and other lithium technologies, making it an excellent option for various lithium battery applications.

10. Scalability and Availabilty: Carbon-coated copper foil is readily accessible for lithium battery manufacturers and easy to implement into large-scale production processes, providing them with easy integration.

Application

◎ Lithium-ion batteries for electric vehicles and、energy storage(LFP、LMFP、LMO、NCM、NCA、LNM、LTO)

◎ Lithium-ion batteries for 3C productions(LCO、LMO)

◎ Supercapacitor

◎ Lithium-ion capacitor

◎ Lithium ion battery in water system

◎ Alkaline batteries