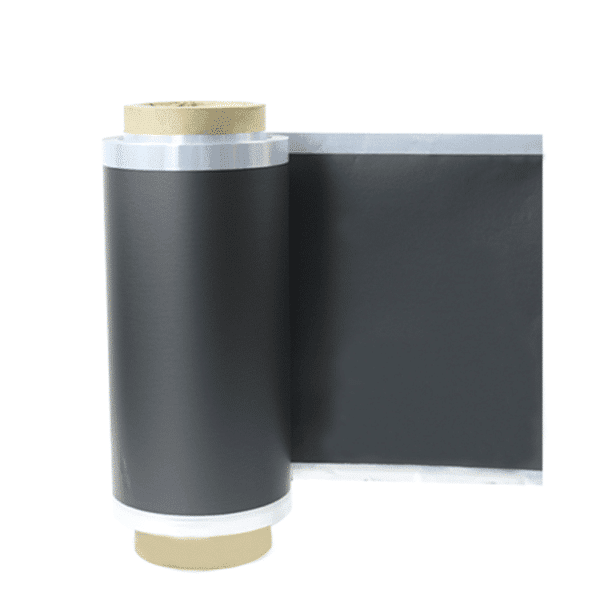

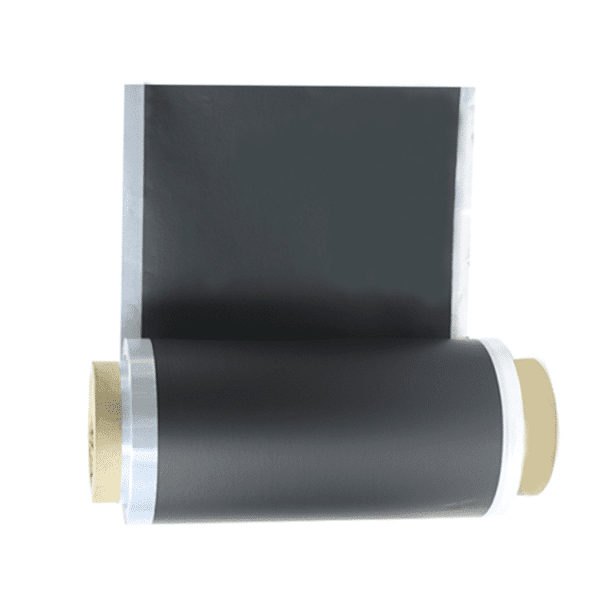

The product is designed as a new type of aluminum foil current collector with uniform coating of graphene on its surface. Based on the excellent electrical conductivity and two-dimensional laver structure of graphene, the ultra-thin layer with a thickness of less than 0.5pm on the surface of aluminum foil has high electrical conductivity, which significantly reduces the interface resistance. and thus improves the adhesion between active materials and aluminum foil. Such a current collector is beneficial to the rate capability and cycle life of battery and supercapacitors. Its comprehensive performance is much better than those of other aluminum foils based on conventional carbon materials. it can replace traditional aluminum foil and corrosion aluminum foil for Li-ion batteries and supercapacitors.

Product Features:

Ultra-thin coating composed of graphene.

Reduce the interface resistance to improve rate capability and cycle life of Li-ion battery and supercapacitors.

Improving the adhesion between active materials and current collector and reducing the corrosion of current collector.

Enhancing the safety of batteries by reducing polarization and alleviating the heating up during charging

| Origin |

Shenzhn China |

| Areal density (double side)/mg cm-2: |

0.04~0.1 |

| Color |

Dark Gray |

| Brand Name |

NSfoil |

| Model Number |

NS-GCAF |

| Product Name |

Graphene Coated Aluminum Foil |

| Coating Thickness (double side)/um |

Typically 0.5 |

| Application |

Li-ion Batteries,Supercapacitors |

| Sample |

Sample Provided |

| Package |

Wooden Box |

Features

Graphene-coated aluminum foil is unique material that combines distinct properties of graphene with aluminum foil. Here are a few of its most important characteristics:

1. Conductivity enhanced: Graphene, a highly conductory material, is applied on aluminum foil, thereby increasing the conductivity of the foil. This increased conductivity allows for more efficient discharge and charge rates, which results in rapid and high power output. energy storage.

2. Large surface area: The graphene coating on the aluminum foil provides a large surface area for electrode-electrolyte interactions. This larger surface area boosts the materials capacitance, leading to an increase in energy storage capacity and performance.

3. Flexible and light-weight Aluminum foil is renowned for its light and pliable properties. When it is coated with graphene the resultant material preserves these properties and is ideal for use in applications requiring light weight and elasticity. It allows the incorporation of supercapacitors and batteries into a variety of devices and systems without adding weight.

4. Mechanical stability The aluminum foil substrate gives an element of mechanical stability to graphene coated. This ensures that the material is able to be able to withstand physical strains and stresses in use, ensuring the structural integrity and quality over time.

5. A high degree of chemical stability Graphene-coated aluminium foil exhibits exceptional chemical stability, which makes it impervious to degrading and corrosion in a variety of electrolyte environments. This stability guarantees the long-term stability as well as performance of the product in tough applications.

6. Low resistance The graphene coating reduces the resistance inside the aluminum foil. This lower resistance permits an efficient transfer of charge between the electrode and electrolyte, reducing energy loss and maximizing the power output.

7. Scalability: Graphene-coated aluminum is compatible with manufacturing processes that can be scaled. Aluminum foil can be found in abundance and the graphene-coated coating is able to be applied by using methods like chemical vapour deposition (CVD) or solutions-based methods. This flexibility makes it suitable for production on a large scale.

8. Thermal stability: Graphene coated aluminum foil has exceptional thermal stability which allows it to withstand extreme operating temperatures. This is especially important for applications where the product could be exposed to high temperatures in the course of its use.

9. Sustainability in the environment: Graphene is a carbon-based material and its application to aluminum foil decreases the need for more environmentally-friendly electrode materials. Utilizing graphene-coated aluminum foils for energy storage devices aids in the creation of more sustainable and environmentally friendly solutions.

It is important to note that graphene-coated aluminum foils are under development and research to improve its performance, cost-effectiveness and production on a large scale. However the combination of aluminum foil and graphene has many possibilities for applications in electronics, energy storage systems and more.