Lithium battery current collectors typically employ aluminum foil as the positive electrode and copper foil as the negative one.

Copper foil is an integral component of lithium batteries. Serving as both current collector and carrier of negative active material, its role as current collector has a direct bearing on cycle life, energy density, safety and other characteristics that define them.

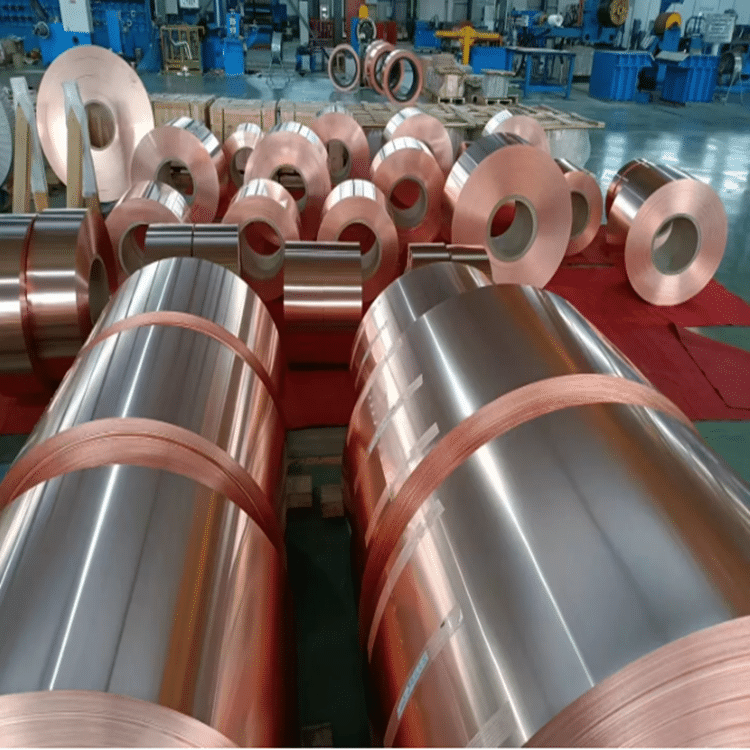

Product Category : Copper Foil for Battery Grade Applications (Single/Double Light, Coated Copper Foil Single/Double Side)

Battery Grade Copper Foil (Single/Double Light): Electrolytic copper foil refers to metallic copper foil produced through electrolysis by using copper as the primary raw material. Copper material is first dissolving to produce copper sulfate electrolyte solution, then electro-deposited via direct current in an electrolytic apparatus to form foil, followed by several treatments such as surface roughening and oxidation resistance treatment. Science Material Station offers copper foil current collectors for laboratory battery research and industrial power battery production that are suitable for lab environments.

Coated carbon copper foil (single/double sided):

Surface modification of battery current collectors using functional coatings is a groundbreaking technological innovation. Modified copper foil is a functional layer that uses multiple or one of several conductive materials to coat the surface of copper foil, forming an excellent two-dimensional or multi-dimensional conductive network structure, which is then combined with a conductive resin suitable for aqueous systems. Through theoretical simulation calculations and multiple experiments, continuous exploration is conducted to find the ratio structure and process conditions. This process can make the surface coating thinner, the coating resistance lower, and the adhesion ability stronger, effectively improving the electrochemical performance and product stability of lithium batteries, especially for silicon-carbon battery systems.

Product Features

| Battery grade copper foil (single/double light) | Battery grade copper foil (single/double light) |

| Excellent electrical conductivity; good chemical stability; good compatibility and bonding strength with electrode active materials; symmetrical double-sided structure; metal density close to the theoretical density of copper; extremely low surface profile; high ductility and tensile strength | Improve the surface tension of copper foil; increase the adhesion between copper foil and active material; improve the energy density and cycle life of batteries; protect current collectors; reduce internal resistance of batteries; improve the rate of charge and discharge performance of batteries; reduce the heat generation of batteries; improve product stability and consistency; improve the production pass rate and battery pack assembly rate of single cells; improve cycle life; reduce production costs |

Product Parameters

[Applicable field]

Battery-grade copper foil (single/double light): negative current collector for various lithium-ion batteries

Coated carbon copper foil (single/double-sided): power storage lithium-ion batteries (SiC), 3C-type lithium-ion batteries (S/C), water-based lithium-ion batteries