High ratio aluminum foil collectors are designed for use in solar thermal applications, specifically in concentrating solar power (CSP) systems. These collectors are made of a special type of aluminum foil that has been coated with a highly reflective material such as glass or polymer. The reflective coating helps to concentrate the sunlight onto a heat-absorbing material, which is typically a metal or ceramic plate or tube.

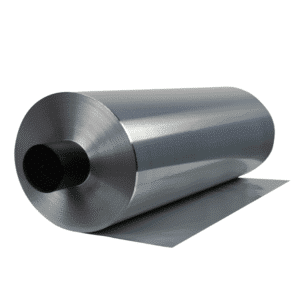

| Application |

Battery anode current collector |

| Type |

Roll |

| Thickness |

0.0055-0.20mm |

| Place of Origin |

Shenzhen, China |

| Temper |

Half Hard |

| Treatment |

Plain |

| Alloy |

3105 |

| Brand Name |

NSfoil |

| Model Number |

NS-AFC5003 |

| Product Name |

High Ratio Aluminum Foil Collector |

| Material |

Aluminium alloy |

| Type |

Aluminum foil |

| Surface |

Plain |

| Width |

MAX2000mm |

| Standard |

ASTM, EN,GB/T 3198-2010 |

| Certification |

ISO9001 ROHS TUV |

| Delivery |

20-40 days |

| Packing |

wooden box |

| MOQ |

3 Tons |

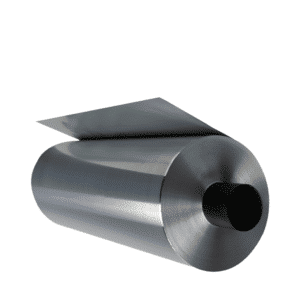

Features

1. High Reflectivity: Aluminum foil coated with reflective surfaces can reflect up to 95% of sunlight that falls upon it, further improving efficiency in solar thermal systems.

2. Lightweight and Flexible: Aluminum foil is both light-weight and flexible, which makes it easy to bend into different forms and install seamlessly into designs with greater design options and reduced installation times. This feature makes installation much faster as well.

3. Durability: Both reflective coating and aluminum substrate have proven themselves durable in harsh outdoor environments, providing this collector with optimal resilience against weathering and corrosion.

4. Cost-Effective: Aluminum foil as the substrate material and reflective coating helps lower production costs compared to other materials commonly found in solar thermal collectors.

5. High Performance: Thanks to their high reflectivity and precise design, CSP systems achieve high solar energy conversion efficiencies which contributes to increased power production from them.

Advantages

◎ Improve the surface tension and increase the adhesion Lithium-ion batteries for electric vehicles between the Al foil and the active material.

◎ Decrease the using amount of binder for the electrode, enhance energy density of the battery ,and lower the cost of the electrode production.

◎ Protect the Al current collector from surface corrosion and oxidation.

◎ Reduce interfacial resistance and internal resistance of the cell.

◎ Decrease polarization and improve the rate capability and specific capacity of the electrode material.

◎ Mitigate exothermal reactions and enhance the battery safety.

◎ Improve the production stability and reproducibility, and raise Lithium ion battery in water system the pass rate of the cell; Increase the consistency and cycling life of the cell and lower the cost of the production