Introduction to Supercapacitors

Welcome to the electrifying world of supercapacitors! These groundbreaking energy storage devices are revolutionizing industries with their high power density and rapid charge-discharge capabilities, but have you ever wondered about what lies behind their success? Allow me to introduce one essential component: the current collector.

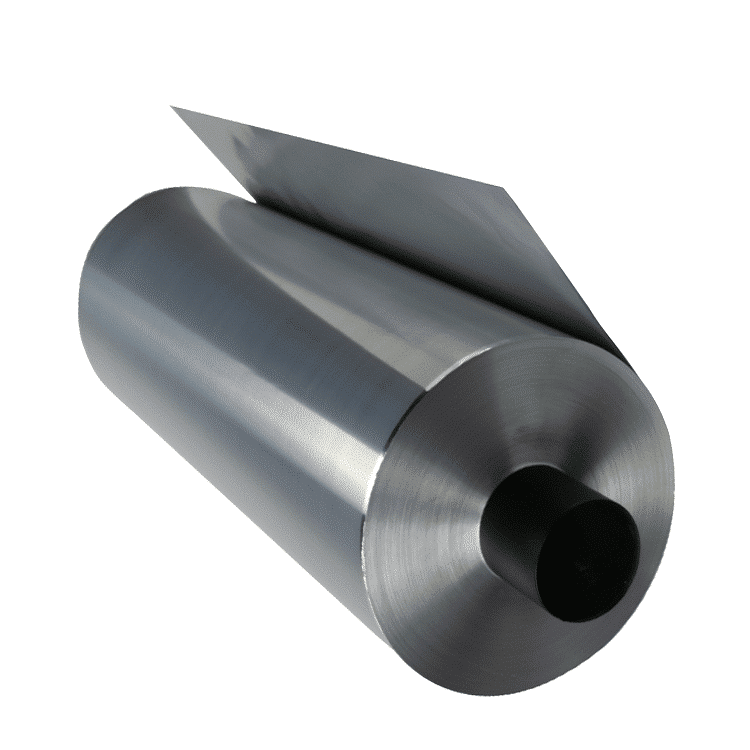

In this blog post, we’ll delve into the fascinating world of supercapacitors’ current collectors – not only traditional materials like copper but also emerging innovations like aluminum foil which is now playing an invaluable role in powering our future! No longer used just for wrapping leftovers anymore – aluminum foil is playing an invaluable part in powering it!

As we embark on an amazing adventure through aluminum foil’s advancement as a current collector for supercapacitors, get ready to be amazed! Prepare to witness how such an unlikely material can have such an incredible effect in pushing boundaries and furthering innovation! Let’s jump right in!

The Importance of Current Collectors in Supercapacitors

Current collectors play an essential part in the performance of supercapacitors. They collect and distribute electrical currents efficiently throughout the device; without proper current collectors, their performance could be seriously impeded.

Current collectors play an essential role in supercapacitors by providing low electrical resistance and high surface area contact between active materials in the supercapacitor and current collectors, thereby improving charge/discharge rates and overall energy storage capacity. Furthermore, current collectors help dissipate heat generated during operation and avoid damage or degradation to sensitive components in supercapacitors.

Traditional current collectors such as carbon-based composites have traditionally relied upon their conductivity properties as current collectors; however, recent advancements indicate that aluminum foil may serve as an attractive alternative material for this application.

Aluminum foil offers several advantages over traditional materials, including its superior electrical conductivity that allows efficient collection and distribution of electrical current within a supercapacitor, its light weight nature being advantageous when weight reduction is key and its lightweight nature.

Aluminum foil provides an efficient method for connecting active electrode materials in supercapacitors with larger surface areas, helping improve charge transfer kinetics and overall energy storage efficiency. Furthermore, its uniform and smooth surfaces help ensure stable electrochemical reactions within the device.

While aluminum foil current collectors provide many benefits to supercapacitors, there are also some challenges associated with using it as current collectors. One major drawback of using it as current collector is its susceptibility to corrosion when exposed to certain electrolytes or operating conditions; researchers are working hard on developing protective coatings or altering alloy compositions in order to address this issue.

As research continues to advance current collector designs for supercapacitors, aluminum foil should become even more effective as a conductor of electrical current.

Traditional Materials Used for Current Collectors

Current collectors play an essential part in the design and performance of supercapacitors, collecting and disbursing electrical currents throughout the device efficiently. Over the years, various materials have been utilized as current collectors in supercapacitors.

Carbon-based materials are widely utilized. Materials like graphite and carbon nanotubes offer excellent conductivity and low resistance, making them suitable for current collector applications. Furthermore, these materials possess impressive mechanical strength for long-term performance under demanding operating conditions.

Metals like copper and aluminum have long been utilized as current collectors due to their superior electrical conductivity. Copper has superior conductivity compared to other metals but may succumb to corrosion issues over time; aluminum provides better corrosion resistance while still offering acceptable levels of electrical conductivity.

Metal foils made of stainless steel or nickel alloys have found use in certain supercapacitors due to their durability in harsh environments, providing reliable performance under any circumstance.

Though traditional materials have served their purpose effectively in many instances, technological innovations continue to push towards more efficient solutions for current collection within supercapacitors.

Stay tuned for our next section where we explore recent innovations involving aluminum foil as an innovative and beneficial alternative that has significant advantages! Don’t miss it – stay tuned!

Advancements in Aluminum Foil as a Current Collector

Supercapacitors have emerged as an impressive energy storage technology, boasting high power density and fast charging times. One key component of supercapacitors is the current collector, which plays a vital role in facilitating electrical charges between electrodes and external circuitry.

Aluminum foil has become an excellent current collector over the past several years, due to recent innovations. While carbon-based fabrics or metal foils such as copper were once the go-to materials for current collection purposes, new developments suggest aluminum foil is also an effective way to do the same job.

One key advantage of aluminum foil is its lightweight nature. When compared with copper foils, aluminum foils are considerably lighter while still offering good electrical conductivity – this weight reduction can lead to more compact and efficient supercapacitor designs.

Aluminum foil’s cost-effectiveness is another major advantage. Aluminum is readily accessible, making it a more cost-efficient alternative than other materials commonly used for current collectors. This accessibility makes supercapacitors more economically viable and encourages wider adoption across various industries.

Manufacturing advancements have allowed for increased surface roughness on aluminum foil, leading to greater adhesion between electrode material and collector surface, thus improving charge transfer in supercapacitors during cycling operations. This enhanced adhesion ensures efficient charge transfer through their systems.

While aluminum foil as a current collector in supercapacitors offers numerous advantages, certain challenges remain. One such disadvantage is lower thermal stability when compared with copper or carbon materials often employed for this application; therefore, proper consideration must be given during operation to temperature restrictions and temperature limitations.

Additionally, corrosion can pose issues when using aluminum foils due to their susceptibility to oxidation reactions. To address this, protective coatings or treatments may need to be applied onto its surface prior to usage.

Conclusion

As technological and research efforts advance to alleviate some of the limitations associated with aluminum foil as a current collector, we may see more developments in this area in the near future.