Are you ready to experience the electrifying world of battery technology? Brace yourself! Today we will unveil one of the unsung heroes behind this revolutionary innovation – the current collector foil. Often overlooked but never underestimated, this unassuming component plays an essential role in powering smartphones, electric vehicles and renewable energy systems – not forgetting smartphones themselves! Join us as we unravel its mysteries while learning more about its role towards creating a greener future – you are about to be charged up with knowledge!

Introduction to Battery Technology and Its Importance

batteries have become an indispensable part of modern life, powering everything from our smartphones and electric vehicles to laptops and game consoles. Unfortunately, their technical component often goes underappreciated or unseen – in this section we will cover its fundamentals as well as its relevance today.

Battery Technology

Battery technology refers to the practices, materials, and processes involved in designing and manufacturing batteries. A battery is a device which stores chemical energy before converting it into electrical energy when necessary; typically composed of one or more electrochemical cells linked together.

Batterys are made up of electrochemical cells, consisting of two electrodes (anode and cathode) separated by an electrolyte solution. When connected to an external load or circuit, chemical reactions take place inside the cell which produce electrons which flow through it as electricity through its circuits.

Importance of Battery Technology

Battery technology cannot be overemphasized. As technological innovations advance and portable device usage increases, batteries have become an indispensable source of power in modern society. Some key reasons for their significance include:

1. Portable Energy Storage – Batteries offer an easy way to store electrical energy for later use without being restricted by wires and cords, making electronic devices such as laptops, smartphones, and tablets available even when there are no nearby power outlets nearby.

2. Renewable Energy Storage – Recently, renewable energy sources like solar panels have become increasingly attractive as sources of power generation. However, storage solutions remain crucial if these sources are to remain effective sources of renewable energy sources such as electricity generation.

What Is a Current Collector Foil?

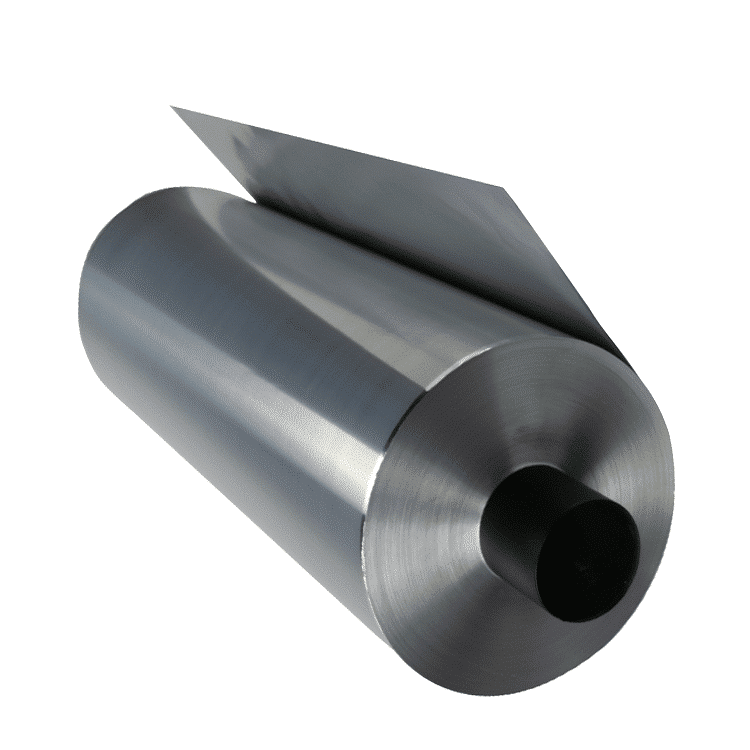

Current collector foil is an essential element in modern battery design, providing an essential connection between its cathode and anode and external circuit, enabling electrical energy to flow.

Simply put, a current collector foil acts as an outlet for electrons generated during chemical reactions inside batteries to travel along. They eventually arrive at their intended destinations such as powering electronic devices or storing energy for later use.

Copper and aluminum are popular choices for current collector foils due to their excellent conductivity and lower cost, though other metals such as nickel, silver, and gold can also be used in specific applications.

One of the key attributes of a current collector foil is its capacity to withstand high levels of stress without breaking down, which is particularly essential given that batteries undergo multiple charging and discharging cycles that put strain on their components. Therefore, selecting a long-lasting material such as stainless steel for this component ensures long battery lifecycle reliability and lifespan.

Current collector foils should also possess low contact resistance with both electrodes. Contact resistance refers to any hinderance to electron transfer at points between different materials; lower resistance means more efficient flow of electrons and improved battery performance.

Current collector foils play a critical role in extracting power from batteries. Their thickness and surface area determine how much can be extracted, respectively.

Current Collector Foils in Battery Technology

Current collector foil is an essential component in battery technology, playing an instrumental role in their performance and efficiency. Acting as an intermediary between electrodes and external circuits, it facilitates electricity from batteries being directed into powering devices such as phones or cars.

Composition and Function

Current collector foils are constructed from highly conductive metals such as copper, aluminum or nickel to maximize conductivity while remaining mechanically strong enough to withstand stresses within batteries. These metals were chosen because of their excellent conductivity properties as well as excellent mechanical resilience – qualities which help ensure maximum battery lifespan and function.

Current collector foils serve a vital purpose: collecting and disbursing electrons produced during electrochemical reactions within batteries. As ions move between electrodes during charging or discharging processes, electrons travel through the current collector foil to generate electricity for electrical energy production.

Types of Current Collector Foils

Current collector foils are an integral component in battery technology, playing an invaluable role in their overall performance. Acting as a bridge between electrodes and external circuitry, current collector foils ensure a steady stream of electrons during charging and discharging processes. Here, we explore their effects on battery performance.

1. Conductivity: One of the primary roles of current collector foils is to provide a low-resistance path for electron flow between an electrode and external circuit, requiring high electrical conductivity to ensure efficient charging and discharging processes. Material choice plays an integral part in this regard; metals such as copper, aluminum and nickel tend to possess excellent electrical conductivity properties and therefore are commonly employed for these foils.

2. Corrosion Resistance:

Current collector foils are exposed to harsh chemical environments within batteries, making them susceptible to corrosion. Corrosion causes resistance levels to increase, ultimately decreasing battery performance. Therefore, when selecting materials for current collector foil designs it is vital that high corrosion resistance properties be considered when choosing material types for current collector foils.

3. Thickness:

Current collector foil thickness can have an immense effect on battery performance. Thicker foils offer lower resistance but can reduce energy density due to increased weight and volume restrictions within a battery cell, while thinner ones allow for more active material, leading to improved energy density and greater energy density overall.

4. Purity: Purity is key when it comes to current collector foil performance, since any impurities in their materials could lead to increased resistance and reduced conductivity, ultimately impacting battery performance negatively. Hence it is vital that high-purity materials be utilized when designing current collector foils.

5. Adhesion:

Current collector foils must adhere securely to electrode material to enable efficient electron transfer during charging and discharging processes, leading to reduced resistance and improved battery performance. Poor adhesion could result in increased resistance or decreased performance.

6.Flexibility: For batteries intended to be bent or folded repeatedly, like those found in portable devices, flexible current collector foils must maintain electrical conductivity under repeated bending or folding, maintaining battery performance consistency over time.

7. Cold Stability:

Current collector foils must also withstand high temperatures without degrading or losing conductivity, to avoid increasing corrosion rates or thermal expansion that would ultimately increase resistance and decrease performance of battery cells.

Current collector foils play an instrumental role in the efficiency and overall performance of batteries. Selecting materials with attributes such as high conductivity, corrosion resistance, appropriate thickness, flexibility, purity and thermal stability is critical for optimal battery operation.

Types of Current Collector Foils Used in Batteries

Current collector foils play an essential part in the performance and efficiency of batteries, helping electrons flow between anode and cathode for storage or discharge of energy. There are various types of current collector foils used within batteries, each offering distinct properties and applications.

1.Copper Foil

Copper foil is one of the most frequently used current collector foils for batteries, thanks to its excellent electrical conductivity, high ductility, and corrosion resistance properties. Copper foil also represents a cost-effective choice among other materials available – making it the go-to choice among battery manufacturers.

2. Aluminum Foil

Aluminum foil is another popular choice for current collector foils in batteries, offering similar properties such as high electrical conductivity and corrosion resistance as copper foil, while being much lighter – ideal for portable electronic devices where weight reduction is crucial.

3. Nickel Foil mes Nickel foil is frequently utilized as a current collector in nickel-metal hydride (Ni-MH) batteries due to its ability to withstand high temperatures without overheating and corrosion from alkaline electrolytes, and excellent mechanical strength which allows repeated cycles of charge/discharge without significant degradation.

4. Stainless Steel Foil

Stainless steel foil is widely used as a current collector in lithium-ion batteries due to its excellent mechanical strength and resistance against high temperatures, making it suitable for large format batteries found in electric vehicles and energy storage systems.

5. Graphite Foil

Graphite foil is an emerging material for lithium-ion battery current collectors, boasting high electrical conductivity with low density to help reduce weight. Furthermore, graphite’s thermal conductivity properties help dissipate heat generated during charging/discharging.

6. Carbon Nanotube Foil

Carbon nanotube foil is an innovative material used as a current collector in advanced batteries and supercapacitors, offering several advantages such as high electrical conductivity, low density and excellent flexibility to allow the creation of thin and lightweight battery designs. Unfortunately, carbon nanotube foils remain more costly than their traditional counterparts due to ongoing commercial development projects.

Battery manufacturers carefully choose their current collector foils based on the requirements and applications of each battery design in order to achieve optimal performance and efficiency. There are various kinds of current collector foils used, each offering distinct properties and applications. Battery manufacturers make careful selection decisions regarding which type to use so as to guarantee optimal performance and efficiency in each case.

Advancements and Innovations in Current Collector Foils

Current collector foils have played a pivotal role in the development and improvement of battery technology. These thin metal sheets form the backbone of batteries, enabling electrons to flow between electrodes while providing energy storage capabilities. As battery technology progresses, so too do materials, designs, and manufacturing processes used for producing current collector foils.

Recent years have witnessed remarkable developments and innovations in collector foil technology that have greatly enhanced battery performance, efficiency, and reliability. Here, we explore some key advances shaping the future of battery technology.

1. Material Selection: Traditional current collector foils have traditionally been constructed from copper or aluminum for their excellent conductivity properties, yet due to rising demands for higher energy densities and longer-lasting batteries, researchers are turning towards alternative materials like nickel or stainless steel which offer greater chemical stability, corrosion resistance, mechanical strength compared to copper or aluminum foils.

2.Micro/Nanostructuring: Current collector foil structure plays an integral part in their performance within a battery cell, and with advances in micro/nanofabrication techniques it is now possible to design current collector foils with tailored structures on either microscale or nanoscale levels. This provides increased surface area contact between active material particles in electrode and current collector foils resulting in improved electron transfer kinetics as well as overall battery performance gains.

Effect of Current Collector Foils on Battery Performance

Current collector foils are essential components in battery technology, playing an essential part in improving overall battery performance. Acting as a conduit between electrodes and external circuits, current collector foils allow electrons to freely flow during charging and discharging processes. We will explore their influence on battery performance here.

1. Conductivity:

Current collector foils play an essential role in providing low resistance electron flow between an electrode and external circuit, necessitating high electrical conductivity to enable efficient charging and discharging processes. Material choice plays an integral part in this determination – often metals such as copper, aluminum and nickel are selected due to their outstanding electrical conductivity properties.

2. Corrosion resistance:

Current collector foils are exposed to harsh chemical environments inside batteries, making them susceptible to corrosion. Corrosion leads to increased resistance levels which ultimately leads to decreased battery performance, making material choice even more critical when designing current collector foils. It is therefore vital that designers select materials with strong corrosion-resistance properties when designing current collector foils.

3. Thickness:

Current collector foil thickness also plays an integral part in battery performance, offering lower resistance with heavier materials but potentially leading to decreased energy density due to weight and volume restrictions within a cell. On the other hand, thinner current collector foils allow more room in each cell for active materials that ultimately results in higher energy density.

Challenges and Limitations Faced with Current Collector Foils

Current collector foils play an indispensable role in battery technology, serving as the intermediary between active material and external circuit. Their primary function is collecting and disbursing electrical current throughout the battery for efficient performance; however, like any component within it they also present challenges and limitations that must be considered when making decisions about purchasing batteries.

One major challenge facing current collector foils is their susceptibility to corrosion. Materials commonly used as current collectors such as aluminum, copper and nickel can quickly oxidize when exposed to harsh chemical environments found inside batteries, leading to resistance increases and conductivity decreases that affect battery performance negatively. To combat this problem, researchers are continually investigating more corrosion resistant materials.

Current collector foils also suffer from low mechanical strength compared to other components in a battery, such as electrodes or separators, making them vulnerable to tearing or breaking under high mechanical stresses during charging and discharging cycles. Furthermore, as batteries become thinner and smaller in size for various applications, it becomes increasingly challenging to maintain structural stability without compromising performance – thus necessitating stronger and more resilient current collector foil materials.

Thickness of current collector foils also poses a limitation on their efficiency. Thicker foils often boast higher electrical conductivity but can add unnecessary weight and volume, lessening battery energy density while making its storage less compact. Thinner foils may improve energy density.

Future Opportunities and Improvement Potential

Current collector foil is an indispensable component in battery technology, acting as an intermediary between electrodes and an external circuit. Although its primary role is energy transfer and storage efficiency, there remains room for improvements that could maximize its effectiveness and increase energy transfer and storage.

One potential area for improvement lies in lowering resistance in current collector foil. Copper or aluminum foils are commonly used, yet have relatively higher electrical resistance compared to more advanced materials like carbon nanotubes or graphene that offer much lower electrical resistance, thus drastically improving battery performance overall.

Researchers are exploring ways to make current collector foil thinner, in order to reduce its weight and increase energy density. Less mass in batteries equates to more space for active materials to store energy – thus leading to lighter batteries with greater capacities.

An exciting potential is using flexible or stretchable materials as current collector foils. Flexible batteries have seen increased use due to their potential applications in wearable devices and electronic skin applications; their ability to conform seamlessly to any surface without impacting performance opens up new avenues for battery-powered technology.

Innovations to current collector foils can further increase their functionality. For instance, creating microstructured surfaces on foils can increase surface area contact between electrodes, improving electron transport routes and decreasing internal resistances – showing promising results in increased power output and cycling stability of batteries.

Conclusion: The Importance of Current Collector Foils

Battery technology relies heavily on current collector foils for efficient functioning and performance. As previously discussed, these foils serve as an intermediary between active material layers and external circuitry to facilitate electron flow into and out of batteries, making current collector foils an integral component in both rechargeable and non-rechargeable batteries.

In this article, we have discussed various current collector foils used in battery technology – copper foils, aluminum foils and nickel foils. Each type offers distinctive properties which make them suitable for different applications; copper foil is known for its superior electrical conductivity and corrosion resistance – making it a top choice for lithium-ion batteries; while lightweight and cost-effective aluminum foil batteries make ideal disposable or low-cost options.

Why are current collector foils so essential? Their main function is ensuring a uniform distribution of current across an electrode surface, to avoid uneven wear-and-tear on certain areas while others remain underutilized, leading to uneven wear-and-tear on electrodes and reduced battery lifespan. Current collector foils help prevent this by evenly disbursing electron flow throughout its layers.

Furthermore, they play a pivotal role in increasing battery energy efficiency by creating low resistance paths for electron flow – helping minimize losses due to heat generation or internal resistance, ultimately improving overall battery performance.