Introduction

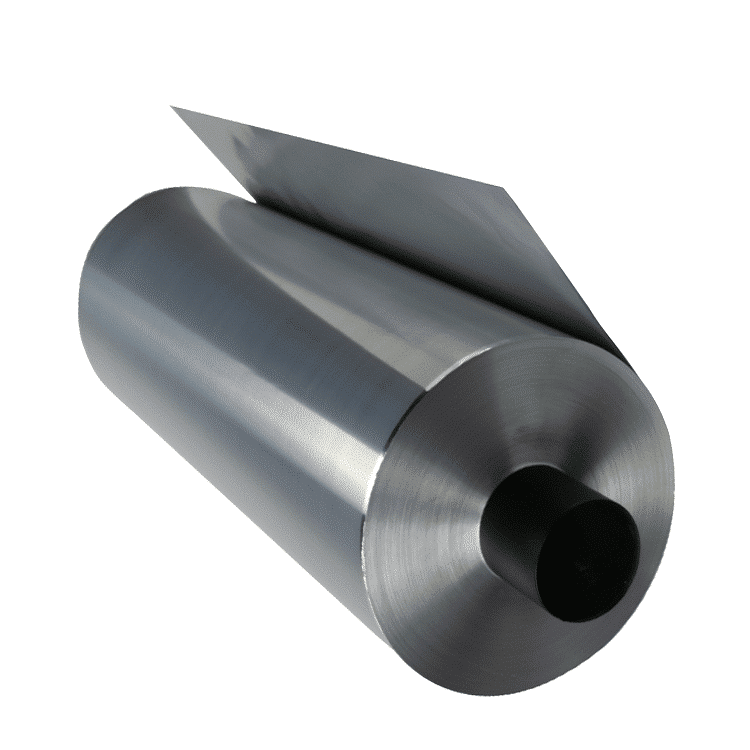

As a crucial component of the lithium-ion battery electrode structure, the current collector serves as a carrier of active materials and a current collector for transmission. Therefore, an ideal current collector should meet the requirements of high conductivity, high stability, low cost, and flexibility and thinness. Typically, aluminum foil is used as the positive electrode current collector, and copper foil as the negative electrode current collector. This is because aluminum undergoes an alloying reaction with lithium ions under certain conditions at the negative electrode, while copper oxidizes at the positive electrode.Aluminum is characterized by its abundant resources, low cost, easy availability, and good ductility.

Compared to traditional aluminum foil, battery-grade aluminum foil has higher performance requirements, pursuing the thinnest thickness, the highest strength, the highest dyne value, the smallest thickness difference, the optimal pattern, and the cleanest surface. It is mainly used in ternary batteries, lithium iron phosphate batteries, sodium-ion batteries, etc.

There are two types of aluminum foil for lithium-ion battery cathodes: flat foil and surface-modified foil . Flat foil has high strength, high conductivity, and high flatness; surface-modified foil, due to its roughened surface, greatly improves the adhesion of active materials, while also reducing the amount of adhesive used, thus improving battery characteristics.

The aluminum foil for the positive electrode current collector in high-end power batteries has a high level of technology. The aluminum foil used for current collectors is mainly made of alloys such as 1060, 1070, 1100, 1235, and 3003, with the mainstream thickness specification being 10-20μm. Some battery manufacturers use 8μm, and the future trend is to continue to reduce the thickness, possibly even to 6μm.

Quality requirements for battery aluminum foil:

Ⅰ. Surface wetting tension

Surface wetting tension is the force exerted between two adjacent parts of a liquid surface per unit length. The magnitude of surface wetting tension is commonly referred to as the “dyne value,” but its more accurate name is the “surface tension coefficient.” Surface wetting tension is one of the most important technical indicators of battery aluminum foil, as it affects the adhesion quality to the coating, especially the coating strength of carbon-coated foil. A low dyne value can lead to defects such as poor adhesion between the aluminum foil and the adhesive material, and incomplete coating. Typically, the dyne value of the aluminum foil surface should be above 30 dyn/mm, and for some high-performance carbon-coated products, it may even reach 33 dyn/mm. A low dyne value is usually considered to indicate a high level of residual oil on the surface.

II. Surface Quality

The cleanliness of the aluminum foil surface is another important indicator. The aluminum foil surface must be free of defects such as black oil lines, dirty oil spots, streaks, roller marks, and color differences . These defects will affect the quality of the battery factory’s coating process and the effect of subsequent rolling. No pits larger than 1mm in diameter are allowed on the surface; pits between 0.5mm and 1mm should be less than 3 per m². Dark sides must be free of raised or bright spots.

III. Plate Shape Quality

This mainly refers to the flatness of the product, which is usually measured by two values. One is the I value achieved by the automatic control of the plate shaper during online rolling, which must be within ±8I. The other value is the amount of product collapse at a specified length during offline tension testing. Different manufacturers and different applications have different requirements for this, but generally the collapse amount is required to be within 8mm.

IV. Thickness

The thinnest thickness of common battery foil has reached 8μm, and the thickness deviation is required to be small, generally within ±4%, and some battery manufacturers require within ±2%.

V. Surface density and end face quality

Areal density refers to the uniformity of aluminum foil thickness. Within the required tolerance range, it should deviate as much as possible in one direction as possible, either positive or negative, to reduce the impact on the shape of the battery cell when the battery is wound or stacked.

The most important quality requirements for aluminum foil end faces are the absence of burrs and serrated cracks. The edges must be free of defects such as V-shaped notches, burrs, and aluminum wires. These requirements are extremely stringent, both to ensure battery safety and to prevent breakage during the rolling process after coating .

VI. Pinhole Requirements

The thickness of battery aluminum foil has decreased rapidly from the commonly used 15μm-20μm to the current 10μm-13μm. The adverse effects of pinholes have gradually become apparent, causing strip breakage during the rolling process, particularly in the blank areas of the electrode. However, leading battery manufacturers do not lower their requirements for the number and diameter of pinholes due to the reduced foil thickness; on the contrary, they demand even higher standards. Theoretically, fewer pinholes and smaller diameters are better. However, given the current technological level and control capabilities regarding the quality of molten aluminum, the requirements for pinholes in battery aluminum foil have essentially reached their limit, regardless of whether the product is hot-rolled or cast-rolled.

VII . Mechanical Properties

Besides gradually reducing thickness, the development trend of battery aluminum foil is towards high strength and high elongation. The reason for increasing the strength and elongation of battery aluminum foil is to meet the high-compaction energy density requirements during rolling while reducing foil thickness. Currently, battery aluminum foil products with a strength greater than 190 MPa and an elongation greater than 2.5% are very common in the market. However, achieving a strength of over 230 MPa and a high level of elongation presents a significant challenge for aluminum foil manufacturers. Currently, North China Aluminum’s high-strength, high-elongation battery aluminum foil products have reached a considerably high level, playing a leading role in the industry.